January 13, 2026

The Manufacturer reports that the Sustainable Markets Initiative (SMI), founded in 2020 by King Charles III when he was Prince of Wales,…

January 13, 2026

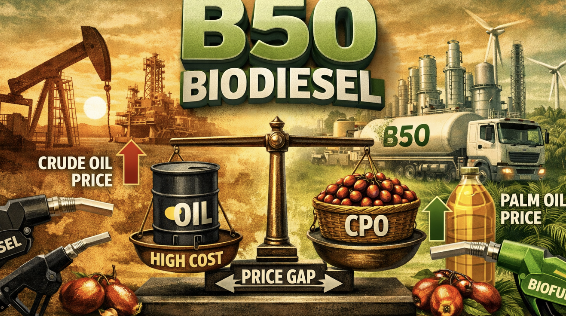

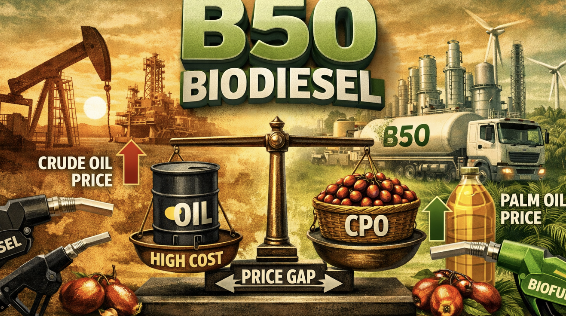

Indonesia’s plan to launch its B50 biodiesel mandate will depend on the price spread between crude oil and crude palm oil (CPO),…

January 13, 2026

Malaysia’s Minister of Plantation and Commodities, Datuk Seri Norliza Ahmad, said that the Malaysian Palm Oil Board (MPOB) plans to officially introduce…

January 5, 2026

Thailand is formally entering a new phase in the development of sustainable aviation. The Ministry of Energy has confirmed that it is…

January 4, 2026

The Indonesian Ministry of Energy and Mineral Resources (ESDM) has set the January 2026 biodiesel Market Index Price (HIP) at IDR 13,631…

January 2, 2026

Canada’s biofuel production incentive officially took effect on January 1, providing immediate support for domestic biofuel capacity and national energy security, according…

January 2, 2026

According to data from the UK Department for Transport, sustainable aviation fuel (SAF) accounted for only 1.6% of total jet fuel consumption…

December 24, 2025

On December 23, an international cargo vessel carrying 17,800 tonnes of sustainable aviation fuel (SAF) produced by Yigao Biochemical Technology (Zhangjiagang) Co.,…

December 22, 2025

French container shipping group CMA CGM and DHL Global Forwarding have signed an agreement to offer lower-carbon container shipping services powered by…

December 19, 2025

On December 18, Neste announced that it has reached an agreement with Cathay Group to supply Neste MY Sustainable Aviation Fuel™ (SAF)…